Now offered in combination with CR Digital’s Thunderbird 1110 drill optimization program, Strayos’ AI platform allows sensor data from Thunderbird to be used in its blast design software to achieve better fragmentation.

Obtaining better blast fragmentation results is a major factor in improving overall downstream performance, and with some recent studies indicating that drilling and blasting combined account for 2% — while processing uses 53% — of total energy input in a typical production scenario, the potential energy savings gained through better blast design are an attractive objective in the industry’s rush to reduce costs and improve efficiency. A few recent product announcements for improved blast-design software offer opportunities for users to maximize blast efficiency.

3GSM GmbH, for example, recently announced several significant updates to its flagship BlastMetriX UAV software. The new version, according to the Graz, Austria-based company, improves communication with smart drills, offers face profiling enhancements and delivers more sophisticated drill pattern analysis.

The enhanced drill pattern analysis tool provides heat mapping of drilled borehole deviations for simple visualization of differences between as-planned and as-drilled patterns. Semiautomatic mapping of linear rock-mass features is imported into the blast plan. By providing enhanced burden and spacing information, the software allows users to adjust explosive amounts in each borehole to account for irregularities.

Updates to the IREDES (International Rock Excavation Data Exchange Standard) interface improves two-way data communication between BlastMetriX UAV and smart drills. It now allows for import of Measure While Drilling data to map the subsurface geology of the borehole. At a quick glance, the software shows the geology and burdens from borehole top to bottom out to the free face. The program is compatible with all major drilling equipment manufacturers.

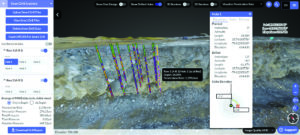

Incorporating the ShapeMetriX system for generating and assessing 3D images, new geological mapping integration allows users to better visualize dips, strikes, seams and voids throughout the drilling pattern. The software, said 3GSM, can characterize irregularities in the face, which are projected back through the borehole. This allows for more precise loading of the borehole and improves blast safety.

With the aid of aerial targets or standard BlastMetriX targets as reference points, the software imports images from a calibrated DSLR camera or unmanned aerial vehicles (UAV) to capture 3D face profiles for enhanced visualization of the blast area. Multiple data-rich overlapping images generate hundreds of thousands of data points for accurately characterizing typography of the surveyed area and creating a 3D face profile.

Earlier this year, AI solution provider Strayos and CR Digital announced new integration between CR Digital’s Thunderbird 1110 drill optimization system and the Strayos blast design and optimization tools. This integration, according to the two companies, will allow mines to leverage the “as drilled” StrataSense MWD data from Thunderbird 1110 within the Strayos blast design platform to tailor explosives to local rock conditions to achieve improved fragmentation at reduced costs.

CR Digital described its Thunderbird 1110 as an OEM-agnostic, high-precision drill guidance and strata measurement system that can be installed on a wide range of production drill rigs.

Strayos said its AI platform offers a full suite of drill and blast design tools. Users can create optimized pattern layouts and charging designs based on drone survey data. The platform automatically assesses blast fragmentation and heave performance from post-blast surveys, and then uses artificial intelligence to learn how to improve future blasts.

In addition, operations utilizing the Strayos blast design tools will now be able to issue the drill patterns directly to the Thunderbird 1110 drill optimization system, so drill rig operators have the latest drill hole geometry available on board. The integrations will be available across all regions in the second quarter of 2022, according to CR Mining.