| The employees at L&H Industrial’s Tempe facility commemorate an expansion. Garrett Goldman is the general manager (far right). |

|

| L&H Industrial’s Tempe, Arizona, gear fabrication shop. |

|

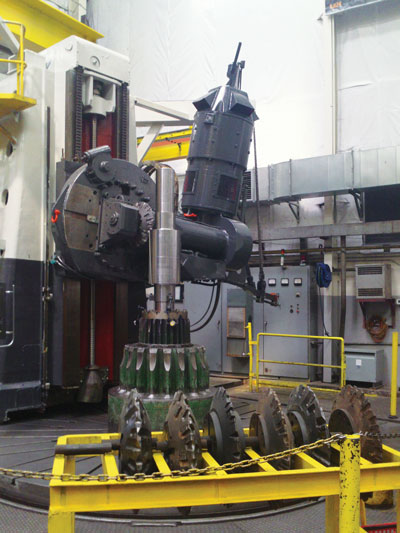

| The Höfler gear grinder. |

On March 26, L&H Industrial held an open house to dedicate a recently completed expansion at its Tempe facility, which specializes in advanced gearing and fabrication. This shop offers custom manufacturing and repair capabilities for large-scale industrial machinery, with an additional focus on industrial machine gears, gearboxes, pinions and pinion shafts. The 60,000-ft2 shop currently has a 100-ton capacity overhead crane for handling massive components and assemblies.

Master tradespeople use cutting-edge technology to design, engineer, manufacture, reband and repair the largest existing gears, weighing up to 110,000 lb (36,287 kg). The highlights of the gear shop include state-of-the-art, industrial-scale CNC machines for horizontal and vertical turning, milling, forming, internal teeth grinding and gear gashing, and internal attachments for gashing splines on large bore shafts. The shop has a horizontal hobber and a Höfler rapid gear grinder, which can handle ring gears up to 236 inches (6 m), just under 20 ft. The shop also offers advanced testing and analysis, including planetary and parallel gearbox transmission testing as well as thermal and vibration analysis.

After L&H acquired this shop from XMS in 2008, it began making significant investments to improve operations. In 2012, they purchased the Höfler for $3.5 million. They placed it in what was the old weld shop, which precipitated the decision to move forward with the new $6.5 million weld shop.

Originally the facility started in 1969 as Goldman Gears. “They specialized in gear shapers, hobbers, etc.,” said Garrett Goldman, general manager of the L&H Tempe facility. “They actually built the pre-gash machine we are still using today. It was one of the first of its kind in the world. There are only three or four other facilities in the U.S. that can do this type of work.”

The new weld shop, which is separated from the gear shop by a sizable breezeway, is where all of the fabrication takes place. “Our gears are predominantly fabricated gears,” Goldman said. “They are forged rings with a web plate. Some have hubs and others do not. They are assembled and welded in this facility. Any project that requires welding on the repair side of the business also comes through this shop.”

Obviously, the Tempe facility receives some really large loads. The trucks can pull into the open air area between the two buildings. The crane rolls out over it, unloads the item and moves it either to the machine shop or the weld shop. Previously the shop had a 20-ft roll-up door and the trucks would have to back into the shop. “Those conditions were challenging,” Goldman said. “This is a big gain in efficiency, and it helps with the overall work flow.”

Soon the Tempe facility will install a second 100-ton bridge crane soon. At that point they will be able to lift 200 tons or flip 100 tons in the air. The crane services both buildings, traversing the breezeway between the weld shop and the gear shop.

The rumor among craftsman at the event was that this shop is the best place in Phoenix to work. L&H made a sizable investment is safety. As an example the shop floor has trenches for electrical cable to prevent tripping hazards. The ventilation system removes all of the smoke efficiently. “We are the only fully air-conditioned weld shop in the Phoenix metropolitan area,” Goldman said.