| Figure 1: Leaky feeder versus node-based post-accident communications systems. |

The 2006 Mine Improvement and New Emergency Response Act of 2006 (MINER Act) required all underground coal mines in the U.S. to have a plan to provide post-accident communication and electronic tracking for any mine workers trapped underground.

In response, post-accident communications and electronic tracking (emergency CT) technologies designed to meet MINER Act requirements have been developed by various manufacturers and approved for permissibility by the Mine Safety and Health Administration (MSHA), meaning they may be used safely in coal mines that may have gassy or dust-laden atmospheres. As a result, more than a dozen different emergency CT systems have become available for U.S. underground coal mining.

The National Institute for Occupational Safety and Health (NIOSH) recently conducted a review of the latest MSHA-approved Emergency Response Plans (ERPs) for each active underground coal mine on file as of February 2014 to identify and characterize the types of emergency CT systems installed. This review pertains only to CT systems installed underground for emergency purposes, and does not include any CT systems installed or used for non-emergency situations, such as communications for everyday operations.

Note that identifying emergency CT systems and their system components can become complicated because some manufacturers use components manufactured by other companies.

In addition, the systems and their various components will often have different MSHA approval numbers associated with them. Accordingly, for simplicity, the overall emergency CT system name listed in each ERP has been utilized for this review.

The key requirement for MINER Act-compliant communications systems is the capability to provide two-way, post-accident communication with the surface for all underground personnel via a wireless medium. This usually involves providing untethered portable communication devices, sometimes referred to as handsets, carried by or available to mine workers as part of the system. Other requirements include battery backup for line-powered equipment, and permissibility for use in conditions where mine ventilation has been compromised.

The MINER Act also requires electronic tracking systems that determine the location of all personnel underground within defined accuracies stated in Program Policy Letter (PPL) No. P11-V-13; for example, to within 200 ft on working sections. Such requirements may necessitate a wireless device for each miner. Requirements for backup power and permissibility are similar to those for communications systems.

|

| Figure 2: Communications and tracking systems by the same or different manufacturers. |

POST-ACCIDENT COMMUNICATIONS

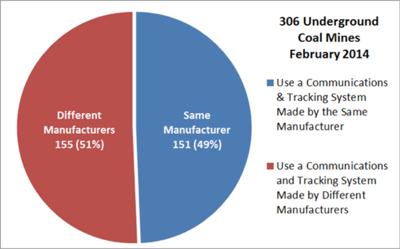

As of February 2014, there were 306 active underground coal mines in the U.S., all using either leaky feeder or node-based post-accident communications systems.

Leaky feeder systems have been around for many years, and have been adapted since the MINER Act was passed to serve as post-accident communications systems. They account for 44% of the installed systems (Figure 1). Leaky feeder systems employ a special type of coaxial cable to enable communications by acting as both a transmission line and an antenna for communication with handsets and other portable devices.

Node-based systems are communications networks installed in a mine; each node is a processor-based device that can link to untethered portable devices such as handsets, as well as to other nodes. Node-based systems may be wired or wireless. As the names imply, wired systems primarily use physical connections between nodes for transmission of communication signals, while wireless systems primarily employ radio links between nodes. Although not common before the MINER Act, node-based systems currently account for 56% of the systems installed in U.S mines. Furthermore, a little more than 60% of these node-based communications systems are wireless. These systems usually do not rely on any physical wired connection for communication from underground to the surface. Also, among node-based systems in service are examples that use both wired and wireless links between nodes, as well as some systems capable of operating as a wired network under normal operating conditions and automatically transitioning to wireless operation if the wired connections are compromised.

|

| Table 1 — All Underground Emergency CT Systems |

ELECTRONIC TRACKING

Most electronic tracking systems determine location by using either communications system nodes or dedicated “readers” installed at known locations underground. These nodes, or readers, detect and recognize uniquely identified electronic devices worn by miners. These electronic identification devices are generally one of two types — “tags” or “integrated handsets.”

Tags provide a continuously repetitive signal, or “beacon,” which is detected by a node or reader.

Many handsets used for post-accident communication systems have tag capability integrated into the device itself, thus eliminating the need for a dedicated tag. If a tag or handset is detected by more than one node or reader simultaneously, software algorithms use the detected signal strength or differential signal time of arrival between the nodes or readers to approximate the location of the tag or handset. Tracking information from the readers is typically transmitted to the surface over some part of a communications system.

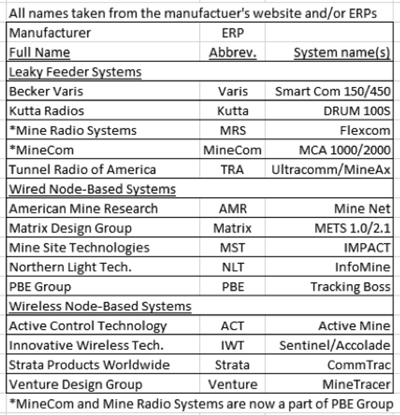

About half of U.S. underground coal mines use the same manufacturer for electronic tracking as they do for post-accident communications (Figure 2). In many of the instances where the mine is using the same manufacturer for both CT requirements, the tracking technology is often integrated directly with post-accident communications through the use of a handset with tracking built right in.

|

| Figure 3: All emergency communications and electronic tracking systems by number of installations. |

SYSTEM MANUFACTURERS

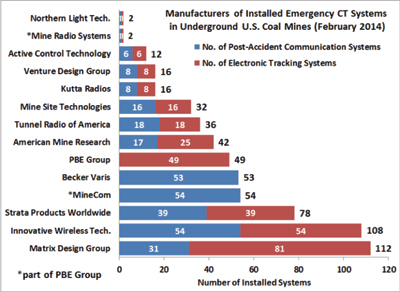

This review showed there are 13 manufacturers of post-accident communications systems currently used in U.S. underground coal mines; five produce leaky feeder systems, four make wired node-based systems, and four supply wireless node-based systems.

A total of 12 manufacturers supply electronic personnel tracking systems used in U.S. underground coal mines. Five manufacturers use tracking tags in conjunction with a leaky feeder communication infrastructure, and three use either tracking-capable handsets or tags as part of a wired node- based system. The remaining four systems provide tracking through an integrated wireless node-based communications system using either tags or handsets with tracking capability.

The accompanying table (Table 1) lists the manufacturers of currently used emergency CT systems, and includes the names under which their systems are marketed. The chart provided (Figure 3) shows the number of systems in service for each manufacturer.

Eight years after passage of the MINER Act, post-accident CT in U.S underground coal mines has evolved to a point where a number of systems based on a variety of CT approaches and technologies are available to mine operators. These advances are expected to greatly enhance miner safety, and it is reasonable to expect that emergency CT systems will continue to change and improve as the underlying technology improves, and as manufacturers adapt their systems to better serve the needs of the mining industry.

The findings and conclusions in this review are those of the authors and do not necessarily represent the views of NIOSH. The mention of any company or product does not constitute an endorsement by NIOSH.

Nicholas Damiano, Gerald Homce and Ronald Jacksha are researchers with the National Institute for Occupational Safety and Health, Office of Mine Safety and Health Research.