When a conveyor isn’t center-loaded, the cargo weight pushes the belt toward the more lightly-loaded side.

As mine managers closely review which new equipment and design options align with their long-term goals, safety will become a new source for cost reduction

by r. todd swinderman

Higher production demands require increased efficiency at the lowest cost of operation, in the safest and most effective manner possible. As conveyor systems become wider, faster and longer, more energy output and more controlled throughput will be needed. Add an increasingly stringent regulatory environment, and cost-conscious mine managers must closely review which new equipment and design options align with their long-term goals for the best return on investment (ROI).

Safety is likely to become a new source of cost reduction. The percentage of mines and processing facilities with a robust safety culture are likely to increase over the next 30 years to the point where it is the norm, not the exception. In most cases, with only a marginal adjustment to the belt speed, operators quickly discover unanticipated problems in existing equipment and workplace safety. These problems are commonly indicated by a larger volume of spillage, increased dust emissions, belt misalignment and more frequent equipment wear/failures.

Higher volumes of cargo on the belt can produce more spillage and fugitive material around the system, which can pose a tripping hazard. According to the U.S. Occupational Safety and Health Administration (OSHA), slips, trips and falls account for 15% of all workplace deaths and 25% of all workplace injury claims.1 Moreover, higher belt speeds make pinch and sheer points in the conveyor more dangerous, as reaction times are drastically reduced when a worker gets clothing, a tool or a limb caught from incidental contact.2

The faster the belt, the quicker it can wander off its path and the harder it is for a belt tracker to compensate, leading to spillage along the entire belt path. Caused by uncentered cargo, seized idlers or other reasons, the belt can rapidly come in contact with the mainframe, shredding the edge and potentially causing a friction fire. Beyond the workplace safety consequences, the belt can convey a fire throughout the facility at extremely high speed.

Another workplace hazard — one that is becoming progressively more regulated — is dust emissions. An increase in the volume of cargo means greater weight at higher belt speeds, causing more vibration on the system and leading to reduced air quality from dust. In addition, cleaning blade efficiency tends to decline as volumes rise, causing more fugitive emissions during the belt’s return. Abrasive particulates can foul rolling components and cause them to seize, raising the possibility of a friction fire and increasing maintenance costs and downtime. Further, lower air quality can result in fines and forced stoppages by inspectors.

Correcting Misalignment Before It Happens

As belts get longer and faster, modern tracking technology becomes mandatory, with the ability to detect slight variations in the belt’s trajectory and quickly compensate before the weight, speed and force of the drift can overcome the tracker. Typically mounted on the return and carry sides every 70 to 150 feet (21 to 50 m) — prior to the discharge pulley on the carry side and the tail pulley on the return — new upper and lower trackers utilize innovative multiple-pivot, torque-multiplying technology with a sensing arm assembly that detects slight variations in the belt path and immediately adjusts a single flat-rubber idler to bring the belt back into alignment.

Modern Chute Design

To drive down the cost per ton of conveyed material, many industries are moving toward wider and faster conveyors. The traditional troughed design will likely remain a standard. But with the push toward wider and higher-speed belts, bulk handlers will need substantial development in more reliable components, such as idlers, impact beds and chutes.

A major issue with most standard chute designs is that they are not engineered to manage escalating production demands. Bulk material unloading from a transfer chute on to a fast-moving belt can shift the flow of material in the chute, resulting in off-center loading, increasing fugitive material spillage and emitting dust well after leaving the settling zone.

Newer transfer chute designs aid in centering material on to the belt in a well-sealed environment that maximizes throughput, limits spillage, reduces fugitive dust and minimizes common workplace injury hazards. Rather than material falling with high impact directly on to the belt, the cargo’s descent is controlled to promote belt health and extend the life of the impact bed and idlers by limiting the force of the cargo at the loading zone. Reduced turbulence is easier on the wear liner and skirting and lowers the chance of fugitive material being caught between the skirt and belt, which can cause friction damage and belt fraying.

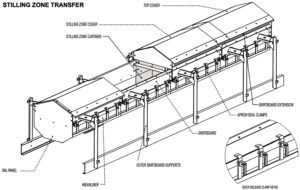

Longer and taller than previous designs, modular stilling zones allow cargo time to settle, providing more space and time for air to slow down, so dust settles more completely. Modular designs easily accommodate future capacity modifications. An external wear liner can be changed from outside of the chute, rather than requiring dangerous chute entry as in previous designs. Chute covers with internal dust curtains control airflow down the length of the chute, allowing dust to agglomerate on the curtains and eventually fall back on to the belt in larger clumps. And dual-skirt sealing systems have a primary and secondary seal in a two-sided elastomer strip that helps prevent spillage and dust from escaping from the sides of the chute.

Modern stilling zones feature components designed to reduce maintenance and improve safety.

Rethinking Belt Cleaning

Faster belt speeds can also cause higher operating temperatures and increased degradation of cleaner blades. Larger volumes of cargo approaching at a high velocity hit primary blades with greater force, causing some designs to wear quickly and leading to more carryback and increased spillage and dust. In an attempt to compensate for lower equipment life, manufacturers may reduce the cost of belt cleaners, but this is an unsustainable solution that doesn’t eliminate the additional downtime associated with cleaner servicing and regular blade changes.

As some blade manufacturers struggle to keep up with changing production demands, industry leaders in conveyor solutions have reinvented the cleaner industry by offering heavy-duty engineered polyurethane blades made to order and cut on-site to ensure the freshest and longest lasting product. Using a twist, spring or pneumatic tensioner, the primary cleaners are forgiving to the belt and splice but are still highly effective for dislodging carryback. For the heaviest applications, one primary cleaner design features a matrix of tungsten carbide scrapers installed diagonally to form a 3-D curve around the head pulley. Field service has determined that it typically delivers up to four times the service life of urethane primary cleaners, without ever needing retensioning.

Taking belt cleaner technology into the future, an automated system increases blade life and belt health by removing blade contact with the belt any time the conveyor is running empty. Connected to a compressed air system, pneumatic tensioners are equipped with sensors that detect when the belt no longer has cargo and automatically backs the blade away, minimizing unnecessary wear to both the belt and cleaner. Additionally, it reduces labor for the constant monitoring and tensioning of blades to ensure peak performance. The result is consistently correct blade tension, reliable cleaning performance and longer blade life, all managed without operator intervention.

A single Roll Generator has enough power output to run a variety of accessories.

Power Generation

Systems designed to operate at high speeds over considerable distances are generally powered only at vital locations such as the head pulley, disregarding adequate power for autonomous “smart systems,” sensors, lights, accessories or other devices along the length of the conveyor. Running auxiliary power can be complicated and costly, requiring transformers, conduits, junction boxes and oversized cables to accommodate the inevitable voltage drop over long runs. Solar and wind can be unreliable in some environments, particularly in mines, so operators require alternative means of reliable power generation.

By attaching a patented mini-generator to idlers and using the kinetic energy created by the moving belt, the accessibility obstacles found in powering ancillary systems can now be overcome. Designed to be self-contained power stations that are retrofitted on to existing idler support structures, these generators can be employed on virtually any steel roller.

The design employs a magnetic coupling that attaches a “drive dog” to the end of an existing roller, matching the outside diameter. Rotated by the movement of the belt, the drive dog engages the generator through the outer housing’s machined drive tabs. The magnetic attachment ensures that electrical or mechanical overload does not force the roll to stop; instead, the magnets disengage from the roll face. By placing the generator outside the material path, the innovative new design avoids the damaging effects of heavy loads and fugitive material.

Bulk Handling, Safety and Automation in the Future

Automation is the way of the future, but as experienced maintenance personnel retire, younger workers entering the market will face unique challenges, with safety and maintenance skills becoming more sophisticated and essential. While still requiring basic mechanical knowledge, new maintenance personnel will also need more advanced technical understanding. This division of work requirements will make it difficult to find people with multiple skill sets, driving operators to outsource some specialized service and making maintenance contracts more common.

Conveyor monitoring tied to safety and predictive maintenance will become increasingly reliable and widespread, allowing conveyors to autonomously operate and predict maintenance needs. Eventually, specialized autonomous agents (robots, drones, etc.) will take over some of the dangerous tasks, particularly in underground mining as the ROI for safety provides additional justification.

Ultimately, moving large quantities of bulk materials inexpensively and safely will result in the development of many new and higher capacity semiautomated bulk transfer sites.

Swinderman is CEO emeritus for Martin Engineering.

References

1 “Slips, Trips & Falls Identification and Prevention,” Occupational Safety and Health Administration, Sacramento, California, 2007. www.osha.gov/dte/grant_materials/fy07/

sh-16625-07/slipstripsfalls.ppt.

2 Swinderman, Todd; Marti, Andrew D.; Marshall, Daniel: “Foundations for Conveyor Safety,” Martin Engineering, Section 1, pg. 14. Worzalla Publishing Co., Stevens Point, Wisconsin, 2016. www.martin-eng.com/content/product/690/safety-book.

Visual inspection is the best way to keep tabs on coal silos.

Silo Inspection and Repair

by steve fiscor, editor-in-chief

Even though they are constructed from concrete, silos are not simply static structures. Dennis Blauser, CEO, Marietta Silos, described them as living and breathing structures that will talk. When they start to talk, coal operators should listen because it may be the first signs of some serious issues.

“The first thing I tell people is to look up at the silo,” Blauser said. “If you’re having problems with the wall, the silo will telegraph that by showing cracks. Once visible cracks develop, the mine should contact a professional silo designer. There are certain firms that specialize in silos. They understand the combination of load paths from both vertical and horizontal loads and this usually exceeds the capacity of a typical structural engineer.”

Keeping a silo clean is really important. If material builds up in a silo, it needs to be removed. The material could fall and cause serious damage to the bottom of the silo. Blauser recommended using a professional silo cleaning company, and cautioned coal operators against trying to do it themselves because of engulfment hazards and other dangers.

Coal operators should also monitor the silo roofs. If the roof is showing signs of deflection or deterioration is visible around the beam pockets, that’s another sign that the mine needs to call a silo expert.

Many years ago, a large silo roof collapsed in Miami and caused a fatality and it has been a driving force for silo inspections nationally, Blauser explained. “If the Mine Safety and Health Administration finds that a mine operator thinks it might have a problem, the agency could instruct the mine to fix the problem,” Blauser said. “If the agency issues a K letter, our job becomes 10 times more difficult because the roof is no longer accessible.”

Coal silos usually have a flat floor or a discharge cone. The discharge cones may not talk as much as the rest of the silo, Blauser explained. “There have been many collapses in the past few decades where suspended cones connected to the silo wall have failed,” Blauser said. “If the silos have large, suspended steel cones, they need to be inspected on an annual or biannual basis. The connection to the silo wall is critical. It’s difficult to see and a layman may not pick up on things an expert would. A lot of problems usually manifest at that connection.”

To properly inspect that connection, the silo has to be cleaned. Instead of hiring engineers to do inspections, some coal operators are hiring silo-cleaning companies that also have the inspection capability.

Silos usually fail because of the forces exerted upon them by loading and unloading. Blauser described it as a combination of load paths coming together. “The wall not only supports the vertical load, but also the horizontal load the materials exert,” Blauser said. “When the mine starts feeding silos, they may not fill the silo uniformly. Ideally, the mine would not like to see asymmetric flow. A flow channel right down the middle is ideal. If that flow channel is askew for whatever reason, it can hit the side of the silo wall and creates a suction force on the wall.”

Concrete is not supposed to bend and crack, but eventually it could move or flex. The external evidence is the cracks, but internally, the bond between concrete and the steel reinforcement weakens and delamination can occur. “The material’s flow characteristics during loading and unloading applies the most load to the silo,” Blauser said.

For an older silo, Blauser recommended inspection every two to five years. If a mine has a problematic silo that is having structural issues, it may want to do it more often, but a good silo designer will provide recommendations in the inspection report for the frequency of inspections.

Once repairs are complete, the coal operators are provided engineering backup or data that tells them what to do. “If the coal company follows the silo designer’s requirements, the silo will function well for a long period of time,” Blauser said, emphasizing the term “silo designer.”

Repair times depend on the nature of the repair. “Some of them can be done quickly, however, some of them require specialized engineering and material procurement,” Blauser said. “We have not seen any major delays due to logistics, but we are seeing minor delays.” With new construction, Blauser explained that delays are less frequent. The difference between the time required to get a silo designed and the time construction starts is usually long enough to secure materials.

Marietta Silos is not currently building any silos for coal operators, but they have been performing a lot of inspection and repair work, and they are working on a few new projects for the power industry.

The best silo monitoring program is one that involves coal operators visually inspecting the silo. “Go out and watch that silo during operations, look up at the silo, look up at the roof, look at the cone, and then when you empty the silo, put eyes on it,” Blauser said. “Technology is great, but your eyes are the most important resource when it comes to taking care of your silo.”