A renewed interest in reducing operating costs, along with the ongoing desire to improve safety, created a perfect environment to take a fresh look at the existing fleet of roof bolting machines to see what could be accomplished. The goal was to take a practical approach to reviewing machine parameters to determine what changes could be made. The emphasis was on changes that would be feasible to roll out to an entire fleet of machines in a short period of time with minimal capital expenditure. The thought process was that significant improvements could be made by simply tuning up the machine parameters to provide a more efficient and safer bolting process.

The typical Fletcher bolter is equipped with a two-section hydraulic gear pump on each side of the machine (see Figure 1). The pumps are fixed positive displacement; as such, they produce a fixed flow rate at a given rpm. The pump sections are sized to deliver 9 gallons per minute (gpm) and 31 gpm for the low-volume and high-volume flow, respectively.

The high-volume pump supplies a fixed displacement gear rotation motor that is coupled to a gear case that rotates the drill steel. Changes to the size of the rotation motor affect the rotation speed and the maximum available torque. The high-volume relief valve controls the pressure. Because torque is a function of the system pressure and the displacement of the hydraulic motor, and the motor is fixed, the relief valve is the device that controls the torque output of the drill. On most drills, the full high volume is available to be delivered to the rotation motor. Some machines are equipped with rotation flow controls to allow the rotation speed to be adjusted for specific conditions, but, in this study, the rotation speed is decreased and the torque is increased by replacing the motor with a larger displacement fixed motor.

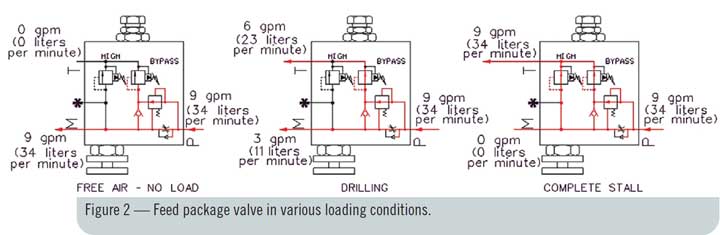

During drilling, the low-volume pump supplies a feed package control valve, which delivers oil to a directional control valve that supplies the feed cylinder. The feed package control valve is perhaps the most important valve involved in the drilling and bolting process. It is also the valve that is most often misused by bolter operators who desire to put the maximum thrust force at their fingertips. When set correctly, the feed package valve (see Figure 2) controls the drilling speed and sets the maximum feed pressure for safety and drilling efficiency. Part of the challenge is to educate mine management on how the feed package valve can be used to improve their safety and performance.

The feed package valve is designed so that the operator can throw the handle wide open on the directional control valve, allowing the feed package valve to control the drilling feed rate. It contains a pressure compensated flow control that will provide a fixed feed rate for drilling. The feed rate will remain constant regardless of the thrust pressure being delivered. The flow control is adjustable so that the feed rate of the drill can be set for various conditions.

When the feed is operated, some oil flows through the flow control, but a high percentage of the oil is bypassed through the compensator portion of the valve. There is a “bypass” relief cartridge in the valve that prevents the bypassed oil from exiting to the tank until the feed pressure exceeds the relief setting. The result is that, when the bit tip is not under a load, the bypassed oil is routed back into the feed supply to provide the full 9 gpm for medium-speed positioning in free air.

Once the feed pressure increases due to a drilling load, the bypass relief valve opens, dumping off the bypassed oil to the tank port. This slows the drilling feed rate to a constant speed based on the amount of oil through the flow control. The final cartridge in the feed package is the high-pressure relief, which sets the maximum feed pressure.

It is important to understand that the feed package is intended to control the drilling process by establishing the feed rate without the operator “feathering” the controls. The high-pressure relief in the feed package valve should be set so that there is never enough thrust force to bend the drill steel. If the feed package is properly adjusted, the feed pressure that is observed in the system will not always be at the maximum setting. Instead, the actual feed pressure will be something less, depending on the strata being drilled at the given feed rate and rotation speed. If the feed rate is increased to the point where the pressure reaches the maximum high relief setting, the drill will begin to slow down because the high relief valve will be open. This is the point where the feed rate must slow until drilling of the hard strata band is complete, at which time the feed rate will again increase to the level set by the flow control cartridge valve.

MODIFYING DRILLING PARAMETERS

Reducing the rotation speed reduces the risk of steel whip. It is also likely that most drills have the potential to rotate at faster speeds than what is required to drill efficiently in typical roof conditions. In fact, while drilling in harder material, it is necessary to reduce rotation speeds to allow the bit to bite into the material instead of skidding and wearing out the bit. The excess rotation speeds could produce excess wear on bits and smaller particle sizes for dust collection systems.

For these reasons, one significant modification for this study was to increase the size of the rotation motor displacement to permanently reduce the drilling speed and increase the drilling torque. The 1.5-in. rotation motor is a very common arrangement. Over the years, the 2-in. rotation motor has been an optional motor that was available, primarily selected by mines that were drilling very hard materials. For this study, the 1.5-in. motors were replaced with 2-in. motors.

Thrust force was the next parameter that was reviewed and optimized as part of the study. Excessive thrust on a drill steel will bend the steel leading to buckling, producing an unsafe condition for anyone in the immediate area. Excessive thrust is a significant contributor to premature bit wear and does little to improve the cycle time of the drilling operation in all but the hardest roof strata.

A dull bit will slow the feed rate and cause more dust fines as the material is pulverized instead of being removed in larger pieces due to proper bit penetration. It is possible that the holes drilled under excessive thrust loads are not as straight because the steel is bowing during the drilling operation. This complicates bolt insertion and makes removing the steel from the hole more difficult because the steel can easily hang in a bowed hole.

Feed rates were a third primary target of the study. The goal concerning feed rates was, first, to ensure that the feed package was controlling the feed rate. This provides a more consistent feed rate by putting the control on the feed package valve instead of the operator. Next, the feed rate would be fine-tuned to provide the fastest possible feed rate without bending the steel or clogging the air flow through the steel. Clogged steels slow the drilling process and can create a blowback of dust, which is a burst of dust backward out of the hole. This burst of dust exposes the operator to respirable dust. The idea was not necessarily to improve feed rates directly, but to optimize the feed rates at the appropriate level as dictated by the strata, drill steel and bit type. Overall, cycle time reduction would then be realized due to the other benefits, such as reduction in steel clogging, drill stalling and time spent changing bits.

The drill torque is set by the high-volume relief valve and the size of the hydraulic motor. For this study, most of the torque improvements were made by increasing the motor size. In all cases, the high-volume relief valve that controls the torque was checked and adjusted to the factory recommendations. However, the setting was not modified to study the effect of more or less available torque on the drilling process. The amount of torque available was simply increased by increasing the displacement of the rotation motors. If a particular mine had an issue of stalling after the larger motors were installed then the high-volume relief valve that controls the maximum torque would have been adjusted to give more torque.

IMPLEMENTING THE CHANGE

J.H. Fletcher worked with several coal mines to make the desired changes to their production machines, determine the effect that the changes had on the drill operation, and draw conclusions about the relative success of the changes when implemented as a package. During a production shift, the machines were observed to find the current status, including the current pressure settings, the drilling methods being used, the type of strata and bits being used, the current drilling feed rate, bit life, noise levels, and drilling cycle times. Once a baseline was established, changes were made to the machine as soon as possible, preferably during the next maintenance shift.

The rotation motors were changed out from the 1-1/2 in. to the 2-in. gear motors, and the feed package settings were adjusted back to the factory recommendations. This provided a good starting point for tuning the machine. Following these modifications, the feed rates were more accurately tuned, and the pressures were further adjusted to obtain the optimum drilling rate. Operators were reoriented with the machine to make sure they understood how the feed package should be used.

Finally, the same parameters that were studied during the initial survey were recorded after the changes had been implemented. The machines were again monitored for one production shift. The results were shared with the operators and then with the mine management. Once accepted by the mine, the changes were implemented on a broader basis at other machines in the same mine. While the improvements were only monitored for one production shift, it should be noted that many of the mines chose to keep and maintain the changes, and are still realizing the improvements.

MACHINE-SPECIFIC RESULTS

There were 12 mines that participated in this testing during 2014, and more machines scheduled for 2015. Following are the specific results from three of the machines operating in Central Appalachia.

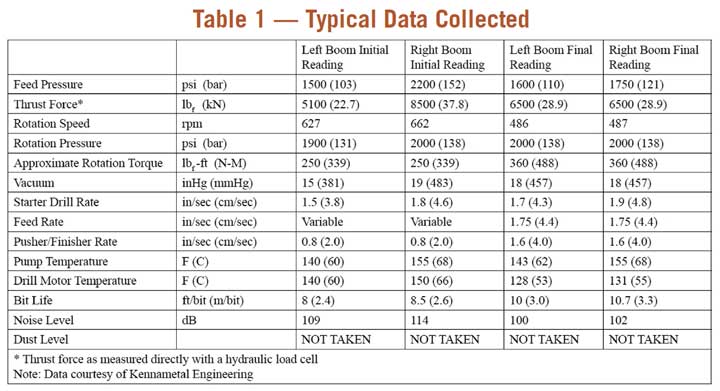

Mine A was operating RRII arm-feed machines. They were installing 6-ft resin bolts supplemented by 14-ft cable bolts. The material being drilled was soft shale for the first 3 to 4 ft and hard shale and sandstone for the remainder of the drilling. The setup included TL-2 drill steels and Kennametal SV119 bits.

During the initial review, the maximum thrust pressure settings were at 1,500 psi and 2,200 psi for the left and right booms, respectively. This meant that one side of the machine had a considerably higher maximum thrust force on the bit. Also, the bypass cartridges were out of adjustment, so the feed package valves were not properly controlling the feed rate.

The rotation speeds averaged 645 rpm, and the rotation reliefs were set at 1,900 psi and 2,000 psi. The feed rate when using the starter tool in the softer material averaged 1.7 in. per second (in/s).

When using the finishing tool in the harder material, very low feed rates were measured at an average of less than 0.8 in/s. The average bit life was 8 ft per bit. The drill steel was clogging on nearly every hole, most likely due to the fast rotation speeds and high feed rates in the soft material.

The clogging of the steel was slowing the drilling process and was creating blowouts, which is a burst of dust out of the hole. The drill was stalling in the harder material above 4 ft. Stalling occurred as the operator reduced the rotation speed to help drill the harder material at the top of the hole. The 2-in. gear-rotation motors were installed, and the drill parameters were set.

The new rotation speeds were approximately 485 rpm on both sides. The new maximum thrust pressure was set to 1,600 psi on both sides so that each side had approximately the same thrust force available. The maximum rotation pressure was turned up just slightly to 2,000 psi on both sides. In the softer material of the first 3-4 ft, the feed rates were set at 1.75 in/s, which was very close to what they were prior to the modifications.

However, the feed rates obtained in the harder material improved to an average of 1.6 in/s, which represented a 100% increase in feed rate. This also demonstrated that the pressure compensated flow control was holding a relatively consistent feed rate, and the high relief was not cracking open. The bit life improved 20% to more than 10 ft per bit. With the increased torque of the larger motors, the operators could slow the rotation in the harder material without stalling the motors. Clogging of the drill steel was virtually eliminated. Noise was observed to decrease by 6 dB as shown on instantaneous readings. This mine chose to implement the changes across the board and is still reporting similar results.

Mine B was operating DDR mast feed machines. They had medium hard, and consistent material to drill. The initial survey showed that the maximum thrust pressure setting was at 1,500 psi for both booms. They were achieving approximately 580 rpm with the 1.5-in. rotation motors. The rotation high-volume relief was set at 1,900 psi on both sides. The feed package valve was out of adjustment for controlling the feed rate.

This set up was drilling with Kennametal SVT119 drill bits and installing 42-in. resin bolts. The feed rate on average was 2 in/s. The bit life was low, requiring 4 bits to bolt a single row. The overall time to install a bolt was 68 seconds.

After the 2-in. gear-rotation motors were installed, the rotation speeds decreased to approximately 475 rpm. The maximum pressure for feed was reduced slightly to 1,450 psi. The maximum rotation pressure was unchanged. The feed rate with the new set up was slightly decreased to 1.75 in/s. The most significant performance improvement observed was in bit life. They were now able to bolt three rows with just two bits.

The overall time to drill and install a bolt was approximately the same. Noise and dust levels decreased. However, the mine will need to perform further testing to quantify the results. This coal company chose to roll out the same changes to all of its mines. They later reported tooling savings of $3,000 per section, per month.

Mine C was operating RRII arm feed machines. Their conditions were soft shale for the first 5 ft of material followed by thin bands of medium hard sandstone for the remaining drilling. They were installing 4-ft resin bolts and 12-ft cable bolts. The setup used TL-2 drill steels and Kennametal SV119 bits. The maximum thrust pressure was recorded to be 1,350 psi on both sides of the machine.

One interesting observation is that the feed package appeared to be tuned close to optimal settings. The rotation high-volume reliefs were set at 1,900 psi. The rotation motors averaged 670 rpm, with the right side being slightly slower than the left. This drill had an initial feed rate of 2.4 in/s in the relatively soft material that they were drilling. The mine was getting good bit life of 52 ft per bit. Plugging was occurring in the soft material. In the harder material at the top, the drill would stall when the operators slowed the rotation speed to approximately 330 rpm for the difficult drilling.

After the rotation motors were changed, the rotation speed was reduced to approximately 500 rpm on both sides. The maximum feed pressure increased slightly to 1,500 psi since this was not enough to bend the steel and the hard conditions needed more thrust. The average feed rate was unchanged at 2.4 in/s, and the bit life was also unchanged at 52 ft per bit. The clogging of the drill steel previously noted was essentially eliminated.

With the increased torque, the operators were now able to slow the rotation speed in the harder bands without stalling the motors. This drill was not able to realize the same improvements to bit life as most machines in the study. This was attributed to the fact that the feed package was properly tuned already. The dust and noise levels appeared to have been reduced significantly, which was attributed primarily to the lower speed of the rotation motors. To date, this mine has elected to not incorporate these changes to its fleet. The test machine was put back to its original condition.

Mine D mine was operating RRII arm feed machines in extremely hard drilling conditions. They were installing 6-ft torque tension bolts and 10-ft cable bolts. The drilling set up included McSweeney’s HOTL 7/8-in. round drill steels, 36-in. starters, drivers, 24-in. middle sections, and finishers. The bits being used were Kennametal RKCV 400 1RR.

The maximum thrust pressure was recorded at 2,000 psi on both sides of the machine, but the feed package was completely out of adjustment, and the operators were setting the feed rate by feathering the joystick. This also results in the pressure staying at the maximum setting with the relief dumping as the hole is drilled.

The rotation motors were running at 650 rpm. Drill steel bending was noted on both booms as the operators attempted to control the feed rate as fast as possible. Steels were hanging in the holes, which resulted from the holes being arched instead of straight. The operators were having difficulty controlling the rotation at medium speeds in the hard material. There was some steel clogging, as well. The bit life was low at 3 ft per bit, drilling at an average rate of 1.3 in/s, but the rate was quite variable and operator controlled.

Because of the extremely hard conditions, this mine was able to achieve significant improvements by changing to the larger rotation motors and tuning the drilling parameters. Immediately, the drill steel bending was eliminated, which provides better operator safety and straighter holes. As a result, the drill tools hung in the hole much less. The maximum thrust pressure reduced slightly to 1,800 psi on both sides, but, because the feed package was set to control the feed rate, the drill ran below the maximum setting during most of the drilling period. The new feed rate was actually improved to 1.6 in/s as controlled by the feed package valve. Bit life saw a substantial improvement to 12 ft per bit, which is a 400% improvement over the initial results.

In addition, the hydraulic system was observed to be operating cooler. The noise and dust levels appeared to have been reduced. This mine elected not to incorporate the changes discussed in this paper. The test machine was put back to its original condition. The mine does see the benefit in the changes, but the main deciding factor was based on the resin in use at this mine requiring high spin speeds. Work is under way to sort this out so that these improvements can be implemented.

RESULTS

Initial Survey: During the initial surveys, it was noted that some drills had high thrust pressure settings well above the recommended settings leading to a high likelihood of steel bending and tool and steel failures. Other machines had their maximum thrust pressure settings close to Fletcher factory recommendations, but most of these still had the bypass cartridge adjusted incorrectly so that the feed package could not control the feed rate accurately. Operators were observed feathering controls in an effort to set the feed rate and installing bolts without use of the two-hand fast feed valve. This demonstrated that the feed package was out of adjustment. Several drills were observed to stall frequently under heavy loads with high feed rates, especially in harder material when the operator attempted to slow the drill speed. In softer material, the drill vacuum system clogged frequently creating blowouts, which is a discharge of dust back out of the hole.

Clogging of drill steels also slows down the overall cycle time for installing a bolt.

Safety Considerations: The maximum rotation speed was decreased on all of the machines to reduce the potential energy of the steel. High thrust loads can lead to steel failure and whipping.

By setting the maximum thrust and controlling the feed rate, the risk due to a steel failure was reduced.

Bit Life: The results were varied, with some mines experiencing no bit life improvement, while others saw dramatic improvement.

Most of the mines did see some improvement in bit life. Some of the more significant improvements were noted when the original feed pressures were considerably off during the initial survey. At least two mines went from using one bit per hole to being able to drill several rows on the same bit.

Feed Rate: Several mines were able to realize significant increases in feed rates by optimizing the settings and proper use of the feed package. A few machines had no improvement in feed rate or even a slight decrease in feed rate. However, the goal was to obtain the appropriate feed rate and to have that rate controlled by the feed package valve. The overall cycle time was improved for all mines, which resulted from other improvements including reductions in stalling, clogging, steel hanging, and time spent changing bits.

Straighter Holes: By eliminating steel bowing, the drilled holes were straighter, leading to a decrease in occurrences of steels hanging in the holes. Hanging steels force operators to have to stop and pull the steel out of the hole. It is common to see the operators pecking or hammering on the side of the steel while pulling it out of the bowed holes. This releases respirable dust from the hole as the steel comes out and places the operator in awkward body positions trying to reach out from under the canopy to free the steel. An operator trying to free a stuck steel may be more at risk for injury.

Drill Stalling: Stalling of the drill motor, which was observed during the initial surveys, was significantly reduced. During the initial studies, stalling was observed rarely in soft conditions, but occurred as much as four to five times per hole in the hardest strata, with an average of two times per drilled hole. After the modifications, stalling was no longer observed on any of the test machines. The improvement can be attributed to the increased torque of the larger motors, as well as setting the feed rates to appropriate levels.

During the drilling of very hard materials, the operators would slow the rotation, which created the stall of the motor. Slowing the rotation speed in hard materials is necessary in order to allow the bit to cut the material with improved bite. This is essential to obtaining good bit life. With the increased torque and the feed rate properly adjusted, this problem improved.

Reduced Clogging: Clogging of the vacuum system was reduced significantly. In the worst scenarios observed, the system would clog on nearly every hole during the initial observation. In harder drilling the clogging was rarely observed because the hard material requires a slower drilling rate. After modifications, clogging was essentially eliminated. This is attributed to the feed rates being set properly and being controlled by the feed package.

Dust Exposure/Cutting Size: The dust exposure is believed to have improved at all mines where the testing was performed.

The size of the cuttings was observed to be much larger after the machine parameters were set and the rotation speed decreased. This was evident by examining the material in the pre-cleaners. The larger cuttings were anticipated since the rotation was now slower for a similar feed rate, thus allowing the bit to bite a larger piece of material per revolution resulting in less fine, respirable dust. The occurrences of steel clogging that led to blowouts were reduced by controlling the feed rate in softer materials. This kept the operators from being exposed to blowout dust. An important observation was made concerning the amount of fine dust being generated. Before the larger motors were installed, when a resin cartridge was inserted in the hole, a large amount of fine dust would fall out of the hole. Once the motors were changed and the drill tuned up, the amount of dust observed coming out of the hole when the cartridge was inserted was significantly less. It is strongly believed that these changes will decrease exposure for the operators. It will be necessary to carry out time weighted operator exposure studies in order to quantify this improvement. Further dust testing is being planned and may be the subject of a future paper.

Noise: Noise rates of the drills were improved significantly. At one mine, the instantaneous noise level was observed to have decreased by 6 dB while drilling hard strata. It is believed that this is the result of a greater portion of the energy going into cutting the material. Further noise surveys are needed to quantify the improvements to the operator exposure on a time weighted basis.

Maintenance Costs: An important result of setting the drill parameters is that wear and tear on the machine is reduced. The drill will run at lower pressures throughout most of the drilling cycle. In one instance, a mine was having ongoing issues with feed cylinder failures. When the machine was reviewed, the pressures were very high. This mine had a torque issue while installing torque-tension bolts, so they were reluctant to reduce the pressure settings. By changing their 1.5-in. motors to 2-in. motors, the torque issue was resolved. Not only did the machine drill better, but the rate of feed cylinder failures decreased significantly. This demonstrates a major benefit of the project: maintenance costs are reduced because the drill does not have to work as hard to drill the holes. Lower temperatures on hydraulic components were noted during the testing. While watching the drill operate, it is easy to see the reduced stress on mechanical components after these improvements are made. Several of the mines that participated in the study later reported notable decreases in maintenance costs on their roof bolters.

Note: The authors of this article are all on staff with J.H. Fletcher in Huntington, West Virginia. Cotton serves as mechanical engineer, Burgess is the vice president of engineering and Martin is the company’s southern district sales manager.