The Tunnel Ridge mine is located in the northern panhandle of West Virginia; the mine was originally built in the mid-1960s as the Valley Camp mine. In 2010, Alliance built a new preparation plant and raw coal conveyor system. The existing clean coal conveyor that had been originally part of the Valley Camp mine was kept in service to transport the clean coal to a loading facility on the Ohio River. A segment of the conveyor crosses Route 2, a major four-lane highway just north of Wheeling. The conveyor crossing consists of two 9-ft diameter tubes, one that is 185 ft long and the other is 176 ft long, and which are 190 ft above the highway. A 12-in. pipe located inside the tubes supplies the preparation plant with water from the river. The site is very constrained because of a steep hillside immediately adjacent to the highway on the east side of the crossing, and a community bicycle path on the west side. The mine uses this conveyor as its only means of moving clean coal to their river loading facilities.

In the fall of 2014, Tunnel Ridge contracted with Industrial Resources to perform a structural inspection, evaluation and analysis of both of these tubes, and the two four-legged towers (one 200 ft tall and the other 40 ft tall) supporting them. This evaluation identified structural deficiencies that had to be addressed for the long term operation of the conveyor. In addition to not impacting the production to the loadout facility, other constraints that had to be considered in developing the plans for the upgrade included the four-lane highway below the one tube, the very steep hillside below the other tube, limited laydown and crane pad areas, the sheer height of the structures, and a pedestrian and bicycle path that had to be kept open. It would be hard to imagine a more difficult site to perform this type of work.

Several conceptual plans were developed and evaluated by the project team. These included upgrading the existing tubes supporting the tubes on new trusses from below, hanging the tubes from new trusses from above, building an entire new conveyor beside the existing tubes, and supporting the tubes on new trusses built around the existing tubes, as well as a number of variations of these ideas. The project team included Tunnel Ridge engineers and managers, as well as the individuals from Industrial Resources. Industrial Resources is a turnkey contractor, and has been delivering engineering, steel fabrication, and construction services to the mining industry for 70 years. In addition to several structural engineers, Industrial Resources’ members included a construction manager and persons experienced with safety, steel fabrication and construction scheduling. This level of experience proved to be the key element in developing the best plan to successfully upgrade the conveyor safely and economically under these difficult constraints. Rather than evaluating each alternative from a limited perspective that may include only the structural design or the costs, the team was able to evaluate all of the other aspects of each alternative that were just as important, or in many cases, more critical to selecting the best concept. Safety, constructability, permit compliance, impact to production, as well as fabrication and delivery issues, were other examples of considerations included as part of the decision-making process.

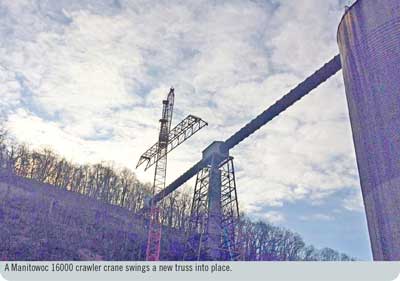

The concept that proved to best meet the project requirements was to provide additional support under the tubes with new trusses constructed around each of the tubes. New support towers would also be constructed around the existing towers. The tops and both sides of the new trusses would be assembled on the ground and lifted into place in one piece. The bottom chords would then be installed in segments. The plan presented very unique challenges. The clearances necessary to erect a 185-ft truss overtop of a 9-ft diameter steel tube 190 ft above a four-lane state highway, without touching the tube during the erection, is one example. How the bottom chords would be installed, positioning and assembling the crane, and traffic control are a few other examples. Finally, all of this had to be executed while not impacting the coal production to the river loadout facility.

The concept that proved to best meet the project requirements was to provide additional support under the tubes with new trusses constructed around each of the tubes. New support towers would also be constructed around the existing towers. The tops and both sides of the new trusses would be assembled on the ground and lifted into place in one piece. The bottom chords would then be installed in segments. The plan presented very unique challenges. The clearances necessary to erect a 185-ft truss overtop of a 9-ft diameter steel tube 190 ft above a four-lane state highway, without touching the tube during the erection, is one example. How the bottom chords would be installed, positioning and assembling the crane, and traffic control are a few other examples. Finally, all of this had to be executed while not impacting the coal production to the river loadout facility.

The key to resolving each of these challenges was ensuring that the correct people with the necessary experience were involved in the process. In addition to the necessary structural design, the trusses and towers each required detailed erection plans that could be executed safely. The input of the construction and safety professionals were just as important as the designers to assure success. Items as small as the structural details were reviewed to assure there were no other alternatives more efficient from an installation or fabrication perspective.

In spring 2015, soil borings were performed to support the design of the new tower foundations and the necessary permits were obtained. After Tunnel Ridge’s procurement process, and with a clear understanding of the selected concept, Industrial Resources was authorized to proceed with a design build contract (DBC) in July 2015 to execute the plan, with a completion date of February 2016.

By early fall the structural design was completed, steel fabrication had begun, the foundations for the new towers had been installed and a traffic control plan had been approved by the West Virginia Department of Highways. The trusses were fabricated and assembled in Industrial’s shop to assure there would not be any problems when assembled in the field. By the end of November, both of the towers and the first truss had been erected. In early December, the new truss over the highway was erected on a Saturday morning. It was picked up at 7 a.m. and the bottom chord was completed by early afternoon.

By early fall the structural design was completed, steel fabrication had begun, the foundations for the new towers had been installed and a traffic control plan had been approved by the West Virginia Department of Highways. The trusses were fabricated and assembled in Industrial’s shop to assure there would not be any problems when assembled in the field. By the end of November, both of the towers and the first truss had been erected. In early December, the new truss over the highway was erected on a Saturday morning. It was picked up at 7 a.m. and the bottom chord was completed by early afternoon.

The project was completed by the end of December, over a month early. And of special importance to Tunnel Ridge, the project was completed safely and in compliance with all regulations, and the project did not impact the mine’s scheduled shipments.

Upgrading aging infrastructure can often be particularly challenging for many reasons. This project demonstrated the power of a cooperative team effort in achieving success on these types of projects. Aging infrastructure can be successfully evaluated and upgraded to deliver the necessary improvements without impacting service to allow it to continue to safely and efficiently operate well into the future.

Author Information

This article was based on a press release submitted by Industrial Resources. Justin L. Leithauser, P.E., senior structural engineer, performed the duties of Project engineer for this project. James F. Wally, P.E., senior design manager, and J. Boyd Rankin, P.E., manager of engineering, also contributed to the project. Raymond A. Perr, P.E., marketing director, contributed to the conceptual planning, and wrote press release. For more information, visit www.indres.com.