Precision Pulley & Idler (PPI) recently launched new Conveyor Cover product line. Conveyor covers help to protect conveyed material and the environment against dust and noise. The covers prevent product loss due to wind and also reduces the amount of wear on the belt due to weather conditions.

Precision Pulley & Idler (PPI) recently launched new Conveyor Cover product line. Conveyor covers help to protect conveyed material and the environment against dust and noise. The covers prevent product loss due to wind and also reduces the amount of wear on the belt due to weather conditions.

With limited suppliers currently in the market, PPI recognized this opportunity to offer conveyor covers as a way to better serve coal operators. “Conveyor covers are a completely new product line to PPI, something we have long considered an important component, as well as something on which we can provide expertise,” said PPI Industry Product Manager Mike Roozeboom. “With the demand of our customer base and the manufacturing capabilities we have today, now is the right time for PPI to expand our offering with this product.”

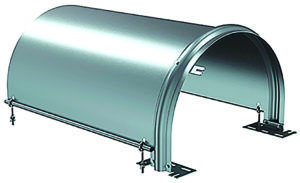

The product will be available in full (180°) and 75% (135°) styles in standard 4-ft long sections. Covers will be made from galvanized steel to protect against corrosion and the elements.

In related news, PPI celebrated the 10th anniversary of its Pro Duty Drum Pulley. This single-drum pulley line that can be used in many applications represented a revolutionary change in the conveyor industry. “Customers have long preferred profiled end discs as they are able to be used in most applications,” Roozeboom said. “The engineered design simplifies choices for miners, so they no longer need to wonder if they should select heavy, mine or quarry duty pulleys. With the Pro Duty, they are confident they have picked the right product for their application.

“Profiled end discs have been proven as a more reliable design than traditional weld-in hubs,” Roozeboom said. “As one of the largest pulley manufactures in the world, we’re able to offer the most dependable pulleys at the same price as traditional designs to maximize our customers’ investments.” The guesswork previously put into choosing a pulley classification has been eliminated, Roozeboom explained.

www.ppi-global.com